Professional Refractory Brick Manufacturer

– SERVING HIGH-TEMPERATURE INDUSTRY GLOBALLY !

– Factory Direct Price.

JianHong Insulation Bricks for Sale

Lightweight Fire Clay Insulation Brick

Al2O3: 20-45%;

Classification Temp: 1200-1300℃;

Bulk Density: 0.6-1.3g;

High Alumina Insulation Brick

Al2O3: ≥48%;

Classification Temp: 1250-1500℃;

Bulk Density: 0.8-1.2g/cm³;

Mullite Insulation Brick

Al2O3: 42-72%;

Classification Temp: 1300-1600℃;

Bulk Density: 0.55-1.1g/cm³;

Alumina Bubble Brick

Al2O3: 85-99%;

Classification Temp: 1500-1700℃;

Bulk Density: 1.4-1.7g/cm³;

Casting Serise Runner Bricks

Refractory Bricks For Sale

Aluminum Silicon Series Bricks

Magnesia Series Bricks

Other Series Bricks

Silicon Nitride Bonded Silicon Carbide Brick

SiC: 66-80%;

C.C.S.: 220-580MPa;

Bulk Density: 2.72-2.80g/cm³;

AZS Brick

ZrO2: 33.5-41%;

Vitreous Phase Exudation: 1.5-3.0%;

Bulk Density: 3.8-4.05g/cm³;

Acid Proof Brick

Acid Resistance ≥: 99.8%

Bending strength≥: 58.80MPa

Bulk Density: 2.31-2.4g/cm³

Checker brick

Material: Silica or high alumina

For hot-blast stoves.

Production: According to drawings

Octagonal Tube Brick

Apparent Porosity≤:19%;

Bulk Density ≥:2.95g/cm³;

Refractoriness Under Load:≥1600 °C

High Aluminum ladle Stopper Brick

Al2O3: 55-80%;

R.U.L.: 1500-1700℃;

Bulk Density: 2.3-2.6g/cm³;

Henan Jianhong Refractory Co., Ltd., founded in 2006 and based in central Henan, specializes in high-quality firebricks for global clients (e.g., steel mills, kiln manufacturers in North America & Europe).

With JIAN HONG REFRACTORY, you benefit from:

- Production Power: Fully automatic batching system, 10 sets of 400-1000 ton presses, 2×168m tunnel kilns, and 20,000㎡ warehouse.

- Tech & Patents: 20+ experts, 1 invention patent (fireway wall firebrick), and application guidance.

- Certifications: ISO 9001/14001/OHSAS 18001, CE, SGS, and High-Tech Enterprise status.

- Service: One-stop solutions, lifetime after-sales support, and custom designs. Jianhong Refractory is more than just a firebrick manufacturer — we are your long-term partner in refractory solutions.

200+

Employees

800+

Successful Cases

40000 ㎡

Factory

130000

Tons Annual Capacity

Our Factory And Workshop

1 Refractory Raw Materials

2 Crushing and Grinding

3 Screening and Mixing

4 Formulation and Batching

5 Molding and Shaping

6 Drying

7 Pre-Firing Inspection

8 Firing in Kiln

9 Firing Completed

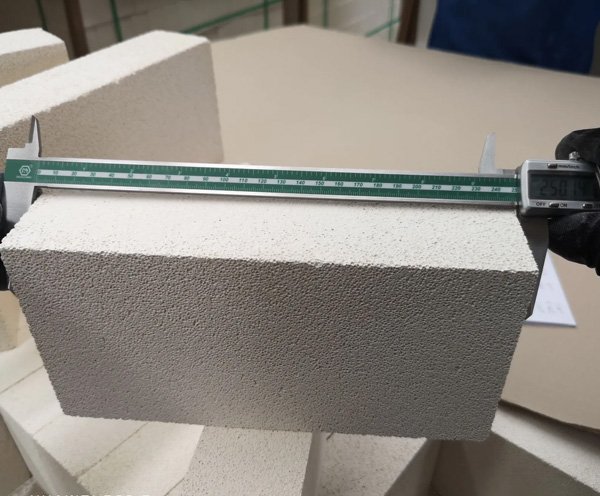

10 Final Quality Inspection

11 Packaging

12 Transport and Delivery

Send us an inquiry for our complete catalog of refractory bricks!