Mullite Insulation Brick

- Al2O3≥: 42%

- Refractory temperature (℃): 1200~1600℃

- Bulk Density (g/cm³): 0.6-1.1

- Cold Crushing Strength(MPa)≥: 1.5-3

- Standard Size: 230*114*65mm

- Certification: ISO9001/ISO14001/ISO45001/ISO50001

- Samples: Provide you free samples for testing

Explore Mullite Insulation Brick

Optimize thermal efficiency with lightweight mullite bricks in customizable sizes and shapes, volume density ranging from 0.5 to 1.2 g/cm³, and use temperatures up to 1600℃. Ideal for kilns, steel plants, and ceramic furnaces, these bricks deliver superior insulation, reducing energy costs and structural load. At Henan Jianhong Refractory Materials Co., Ltd., we offer a comprehensive range of mullite insulation bricks designed to meet the varied demands of industrial furnaces, kilns, and metallurgical plants around the world.

Mullite insulation brick standard size brick

- Specifications: 230×114×65mm (standard size)

- Advantages: mass production, uniform precision, easy installation

- Applications: conventional thermal insulation scenarios such as metallurgical kilns and ceramic roller kilns

- Certification: in accordance with GB/T 3003-2020, suitable for 90% of industrial conditions

Mullite insulation brick special size brick

- Customization: arc/trapezoidal/perforated bricks according to drawings, error ≤ 0.3mm

- Efficiency: Accurately fit the kiln surface and complex working conditions, improving insulation efficiency by 20%

- Applications: high temperature furnace bends, special-shaped interfaces of chemical pipelines, special insulation layers of environmental protection equipment

Mullite insulation brick Bulk Density

- Bluk density: 0.5~1.2g/cm³, thermal conductivity as low as 0.17W/(m・K)

- Advantages: Weight reduction of 50%+, construction efficiency improvement of 30%, energy saving rate of 40%

- Applications: Reduce kiln weight, enhance insulation, and lower fuel consumption, making them a preferred energy-saving choice.

Mullite insulation brick grades

- Grade: JM23, JM26, JM28, JM30/K23, K26, K28, K30

- Selection on demand: From low-temperature energy saving to high-temperature strong corrosion resistance, full grade coverage, JIAN HONG Refractory provides you with working condition matching solutions free of charge!

Why choose Jianhong Refractory?

If you’re in search of the finest Mullite Insulation Brick for optimal solutions to serve your clients, look no further than Jian Hong Refractory. Our meticulous practices ensure the delivery of top-tier High Alumina Refractory Bricks.

Low MOQ

Jian Hong Refractory offers flexible production, accommodating orders from 1 to 10,0000 units on demand.

Fast delivery

Our mature production line facilitates 24/7 operations, enabling rapid turnaround and prompt delivery.

Competitive Price

We guarantee the most competitive prices while maintaining the highest quality standards compared to other suppliers.

Expert Production

Equipped with three modern production lines, our facilities ensure consistent quality and timely delivery, setting us apart from others in the industry.

Satisfaction Assurance

With a focus on refractory product quality and clear communication, we ensure that every step is streamlined for the ease and satisfaction of our clients.

Comprehensive Product Range

Beyond high alumina bricks, our portfolio includes castables, insulation bricks, ceramic fiber products, and refractory raw materials, providing a one-stop solution unlike competitors with limited ranges.

1 Refractory Raw Materials

2 Crushing and Grinding

3 Screening and Mixing

4 Formulation and Batching

5 Molding and Shaping

6 Drying

7 Pre-Firing Inspection

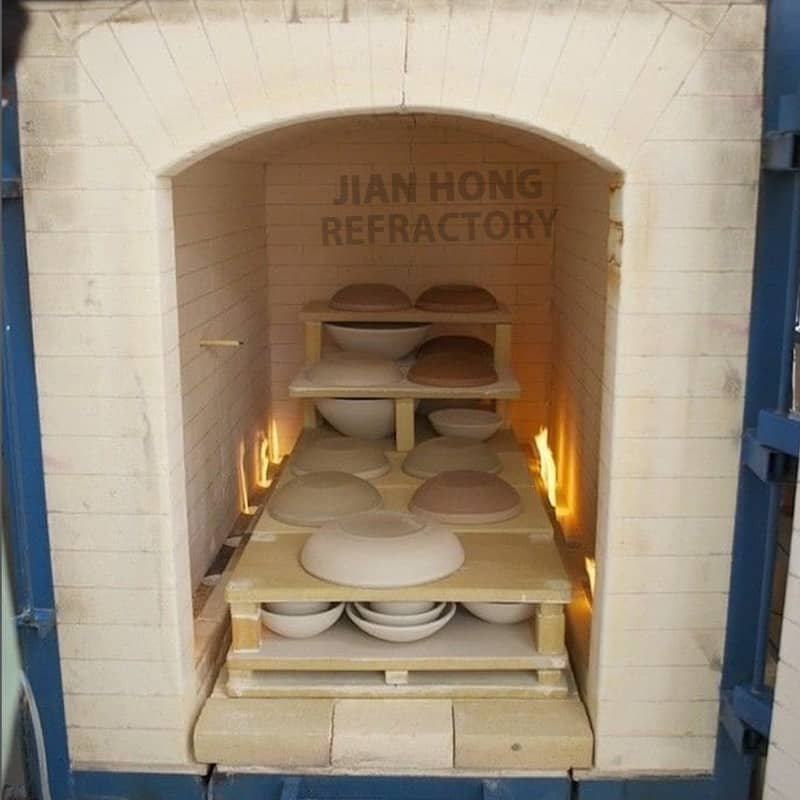

8 Firing in Kiln

9 Firing Completed

10 Final Quality Inspection

11 Packaging

12 Transport and Delivery

The Ultimate Buyer’s Guide: How to Purchase Mullite Insulation Brick

Are you in the market for mullite insulation brick? Look no further.

This all-inclusive buyer’s guide provides you with crucial insights into mullite insulation brick, which find applications in metallurgical industry, power industry, ceramic industry, chemical industry and other heat treatment high temperature industries. Whether you’re contemplating importing them for your projects or planning local distribution, this guide furnishes invaluable information to guide your decision-making process.

Table of contents

Chapter 1

What is Mullite insulation brick?

Mullite insulation brick, also known as mullite lightweight brick, are high-performance aluminosilicate refractory materials designed for superior thermal insulation in high-temperature industrial applications. With alumina content ranging from 40% to 77%, these energy-efficient insulation brick deliver excellent heat resistance and low thermal conductivity, making them ideal for kilns, furnaces, and high-temperature processing equipment. Manufactured using expanded mullite ore through high-temperature sintering, these lightweight refractory brick feature a bulk density of 0.55–1.35 g/cm³ and a compressive strength of 1.2–4.5 MPa. Low-alumina variants contain glass phase and cristobalite, while high-alumina types include traces of corundum. Capable of direct flame contact, mullite insulation brick are a trusted choice for industries seeking long-lasting, cost-effective thermal protection.

Chapter 2

Features of Mullite insulation brick

- Reliable Thermal Insulation for High-Temperature Systems

Mullite insulation bricks offer low thermal conductivity, effectively reducing heat loss and boosting energy efficiency in kilns, industrial furnaces, and other high-temperature systems. - Lightweight Yet High-Performance

Designed for stability in harsh, reducing atmospheres, these lightweight Mullite Insulation Brick resist chemical corrosion—thanks to added calcium—for long-term, high-temperature use. - Thermal Shock Resistance You Can Trust

These bricks handle sudden temperature changes without cracking, making them ideal for metallurgical furnaces, steel production, and continuous thermal operations. - Durable and Corrosion-Resistant

Despite their low weight, mullite bricks feature a strong structure with high compressive strength and excellent corrosion resistance, ensuring long-lasting performance in demanding refractory applications.

Chapter 3

Specifications of Our Mullite insulation brick

| Item/Grade | JM23/K23 | JM26/k26 | JM28/K28 | JM30/K30 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Al2O3(%) | 42 | 45 | 54 | 55 | 56 | 64 | 65 | 66 | 72 |

| Fe2O3(%) | 1.2 | 1 | 0.9 | 0.8 | 1 | 0.75 | 0.65 | 0.65 | 0.55 |

| Bulk Density (g/cm³) | 0.6 | 0.8 | 0.7 | 0.8 | 0.9 | 0.8 | 0.8 | 1 | 1 |

| Cold Crushing Strength/MPa | 1.5 | 2.3 | 2 | 2.3 | 2.8 | 2.3 | 2.8 | 3.3 | 3 |

| Permanent Linear Change/% | -0.55 | -0.4 | -1 | -0.65 | -0.5 | -1 | -0.8 | -0.7 | -0.9 |

| 1260℃×12h | 1300℃×12h | 1400℃×12h | 1400℃×12h | 1400℃×12h | 1500℃×12h | 1500℃×12h | 1500℃×12h | 1600℃×12h | |

| Thermal Conductivity 350℃ ≤/[W/(m·K)] | 0.19 | 0.24 | 0.21 | 0.25 | 0.3 | 0.28 | 0.32 | 0.34 | 0.4 |

Chapter 4

Application of Mullite insulation brick

Mullite lightweight insulation bricks are specially engineered for industries requiring superior thermal insulation, reduced structural load, and long-term durability in high-temperature environments. Manufactured from high-purity mullite and advanced foaming techniques, these energy-saving insulation bricks are widely used in thermal systems where both performance and efficiency are critical.

Iron and Steel Industry

In the steel industry, mullite lightweight insulation bricks are mainly used in heating furnaces, soaking furnaces, and annealing furnaces. They are ideal for insulation layers or non-flame-contact working layers due to their low thermal conductivity, low heat capacity, and strong thermal shock resistance.

Ceramic Industry

In the ceramic industry, mullite lightweight insulation bricks are mainly used in roller kilns for high-temperature energy saving and weight reduction. Their low density, high insulation, heat resistance, and excellent thermal shock resistance make them ideal for ceramic production.

Non-Ferrous Metals Industry

In non-ferrous metal smelting, high-temperature equipment like blast furnaces, rotary kilns, and electrolytic cells face challenges from heat, corrosion, and energy loss. Mullite lightweight insulation bricks, with their light weight, high strength, heat resistance, and low thermal conductivity, are ideal for these areas—helping the industry reduce costs, improve quality, and cut emissions.

Glass Industry

In the glass industry, kilns are key high-temperature equipment that affect product quality and cost. Mullite lightweight insulation bricks are ideal for glass melting kilns and annealing kilns due to their high-temperature performance and structural strength, helping the industry achieve both energy savings and higher efficiency.

Petrochemical Industry

In the petrochemical industry, core equipment like cracking furnaces, reformers, and reactors operate at 800–1400°C and face sulfur corrosion, thermal shock, and high energy consumption. Mullite lightweight insulation bricks, with their heat resistance, corrosion resistance, energy-saving, and long lifespan, are key materials for energy upgrades and equipment improvements, helping achieve safe operation, cost reduction, and green production.

Chapter 5

Quality Assurance for Mullite insulation brick

At Henan Jianhong Refractory Materials Co., Ltd., we are committed to delivering premium-grade mullite lightweight insulation bricks that meet the highest industry standards. Our quality assurance process is designed to ensure each product offers consistent performance, long service life, and maximum thermal efficiency.

The key quality tests typically include:

| Test items | Test Description | Testing standards |

|---|---|---|

| Bulk Density (BD) | Measures the compactness of the brick. High density often correlates with better strength and durability. | ASTM C133 |

| Apparent Porosity (AP) | Indicates the brick's ability to resist slag and gas penetration. Lower porosity is preferred for corrosive environments. | ASTM C20 |

| Cold Crushing Strength (CCS) | Indicates the brick's ability to resist slag and gas penetration. Lower porosity is preferred for corrosive environments. | ASTM C133 |

| Refractoriness (RUL & PCE) | RUL (Refractoriness Under Load): Measures the temperature at which the brick deforms under load. | ASTM C24 |

| PCE (Pyrometric Cone Equivalent): Indicates the maximum temperature the brick can withstand without melting. | ||

| Thermal Shock Resistance | Evaluates the ability to withstand rapid temperature changes without cracking. | ASTM C1171 |

| Thermal Conductivity | Assess insulation performance — lower conductivity is ideal for insulating bricks, while higher values suit heat-transfer zones. | ASTM C1171 |

| Chemical Composition Test | Check the amounts of key ingredients like aluminum oxide (Al₂O₃), silicon dioxide (SiO₂), and magnesium oxide (MgO) to make sure they meet the required levels for the intended use. | ISO 12677 |

| Slag Resistance/Erosion Resistance | Evaluate the resistance to slag or chemical media. | ASTM C24 |

| Reburn line Change Rate | Volume stability after high temperature heating. | ASTM C38 |

| Dimension Inspection | Measure the length, width, and thickness of the bricks to make sure the size error is within ±1mm. This ensures the bricks match customer requirements and fit accurately during installation. | ISO 5019-1 |

| Surface Appearance Tests | Surface cracks.Edge chipping.Consistency in color and finish. | ISO 5019-1 |

| Packaging Tests | Packaging is inspected for export compliance and damage protection |

Through this meticulous testing process, we ensure that our refractory bricks meet the highest standards of quality, reliability, and performance, making them ideal for various applications in various industries.

Chapter 6

Actual construction case demonstration of Mullite insulation brick

Our mullite lightweight insulation bricks have been successfully applied in multiple high-temperature industrial projects across North America and Europe. In one case, a leading steel mill in the United States upgraded the insulation lining of its annealing furnace using our bricks, achieving a 15% reduction in fuel consumption and significantly improved thermal stability. In another project, a ceramic kiln manufacturer in Germany used our bricks in a roller kiln, enhancing heat retention while reducing the overall furnace weight. These real-world construction cases demonstrate the efficiency, durability, and energy-saving benefits of our mullite insulation solutions, earning long-term trust from global clients in steel, ceramic, and petrochemical industries.

Chapter 7

Chapter 8

In Summary

When it comes to mullite lightweight insulation bricks, Henan Jianhong Refractory Materials Co., Ltd. stands as your trusted partner in delivering exceptional quality, reliability, and performance. With over two decades of expertise, we specialize in manufacturing premium refractory products engineered to withstand extreme temperatures and harsh industrial conditions. Our commitment to precision, stringent quality control, and comprehensive customization ensures that every brick we produce meets the highest industry standards.

Partner with us and experience the advantages of working with a dedicated supplier known for superior product consistency, timely delivery, and unwavering customer support. From steel plants to cement kilns, our high-alumina bricks are designed to maximize your operational efficiency and protect your high-temperature systems effectively.

Ready to enhance your industrial operations? Connect with Henan Jianhong Refractory Materials Co., Ltd. today and let us be your trusted source for reliable, high-performance refractory solutions.